Electron is ready to supply X-ray systems of its own production for non-destructive testing of products (NDT) - both ready-made and adapted for tasks in accordance with the technical specifications of the Customer.

The company's product portfolio includes solutions using X-ray sources with accelerating voltages of 20 - 450 kV. We use a wide range of key components of X-ray technology to create systems for various fields of application. All x-ray equipment is based on modern imaging systems based on digital X-ray detectors.

We have the necessary resources, competencies, experience in the development and manufacture of X-ray systems for various applications, both for serial production and in accordance with the individual requirements of the Customer.

EQUIPMENT FOR X-RAY NON-DESTRUCTIVE TESTING

Digital Radiography Systems

- Stationary and portable system design according to the requirements of the Customer

- Image quality class B and above in accordance with GOST ISO 17636-2 2017

- Digital flat panel detectors

- Size of active area: from 26x36 mm to 430x430 mm

- CMOS and TFT (a-Si) technologies

- Pixel sizes: from tens to hundreds of microns

- Scintillators CsI and Gd2O2S (GOS)

- X-ray assemblies and power supplies

- From 20 kV to 450 kV

- Focal spot from units of microns to units of mm

- Portable and stationary design.

- Operator’s AWS

- Shockproof and dustproof industrial design for portable devices

- Intuitive Russian-language touchscreen interface

- Customizable digital imaging filters

- DICONDE format support

- Transport case (for the installation) or backpack (for the digital imaging system) for portable equipment

- Supports wireless mode

- Extended operating temperature range: from -35 ° С to + 50 ° С

- Reducing the time of control, increasing efficiency and objectivity of control

- Reducing the cost of consumables (X-ray films and chemicals) and auxiliary equipment (developing machines and accessories for drying and storing film)

- Archiving of control results in digital form

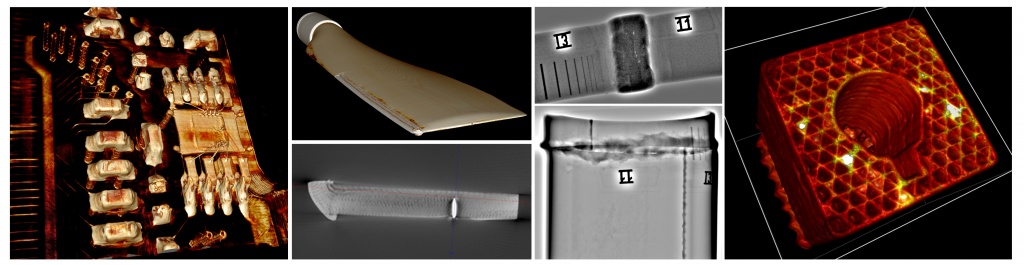

X-ray television and tomography systems

- Modular type of system design, adaptation to the Customer's requirements

- Open and cabin design

- Work with geometric magnification up to 3000 times

- 2D inspection in real time

- All-round view of the object: from 0 ° to 360 °

- Tomography (3D reconstruction)

- Dimensions of the examined objects: from 10 cm to 240 cm

- The mass of the examined objects: up to 200 kg or more

- Design of systems for other weights and dimensions of objects according to the requirements of the Customer

- Minimum dimensions of detected defects: units of microns

- Sources of radiation: from 20 kV to 450 kV

- Digital flat panel detectors

- Size of active area: from 26x36 mm to 430x430 mm

- CMOS and TFT (a-Si) technologies

- Pixel sizes: from tens to hundreds of microns

- Scintillators CsI and Gd2O2S (GOS)

- "Virtual detector" (increasing the volume of reconstruction)

- Operator's software

- Customizable digital imaging filters

- DICONDE format support

- Archiving of control results in digital form

CUSTOM-BUILT DEVELOPMENTS AND SCIENTIFIC AND TECHNICAL COOPERATION

- Ready for projects on the development/layout of installations for digital X-ray control (radiography, fluoroscopy, tomography) according to the requirements of the Customer, including the Customer's R&D.

- We have experience in working with government customers as the lead contractor and co-executor of state R&D contracts on the topics of digital X-ray control, precision mechanics systems, X-ray installations for various applications.

- We offer contract engineering for the supply of various NDT equipment, including support for integration at the Customer, supply of individual components and software.

- We provide services in X-ray diagnosis (digital radiography, fluoroscopy, industrial tomography).

- Verification of customer samples to obtain quick results, demonstrate the capabilities of digital control technologies and joint development of requirements for systems.

INDUSTRIES FOR THE APPLICATION OF SOLUTIONS

- Creation of digital models of objects

- Reverse engineering (copying)

- Metrology including internal measurements and 3D measurements

- Quality control of blanks and parts (casting, stamping, machining, soldering)

- Control of manufacturing and assembly of precision mechanics

- Inspection of welds and joints

- Core sample control

- Detection of contaminants in food products, geometry, and filling of packaging

- Analysis of failures and technical condition of objects

- Digitization of works of art

- Quality control of medical devices and pharmaceuticals

- Control of micro- and radioelectronic components

- Control of biological objects, preclinical studies

- Counterfeit detection

- Production of rare and critical spare parts for the restoration and repair of equipment, etc.

Contact us:

Phone: + 7 (812) 325 02-02

Fax: +7 (812) 325 04-44

E-mail: ndt@electronxray.com